Décor Unit 700 - 2500 Spray and Seeding

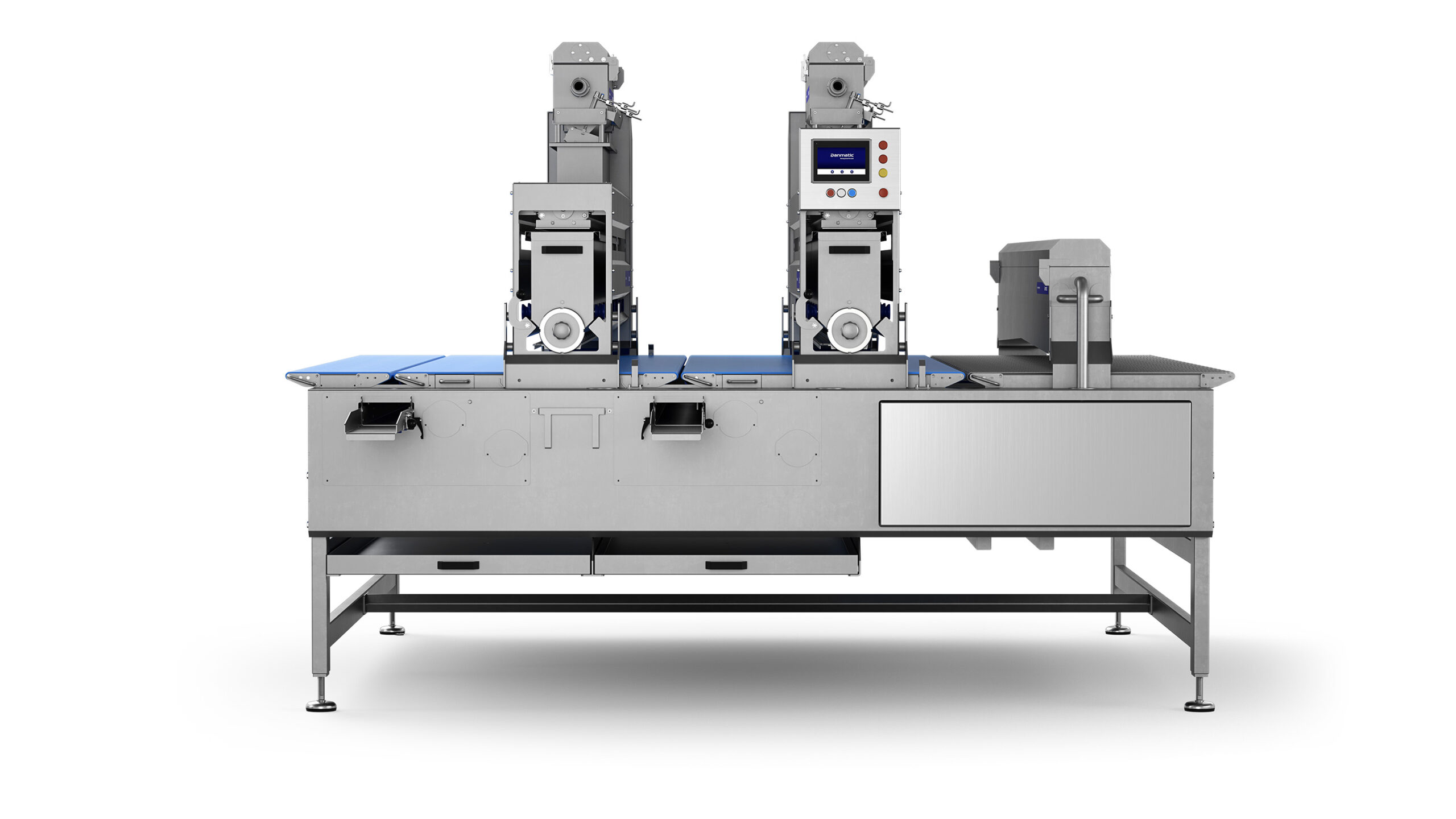

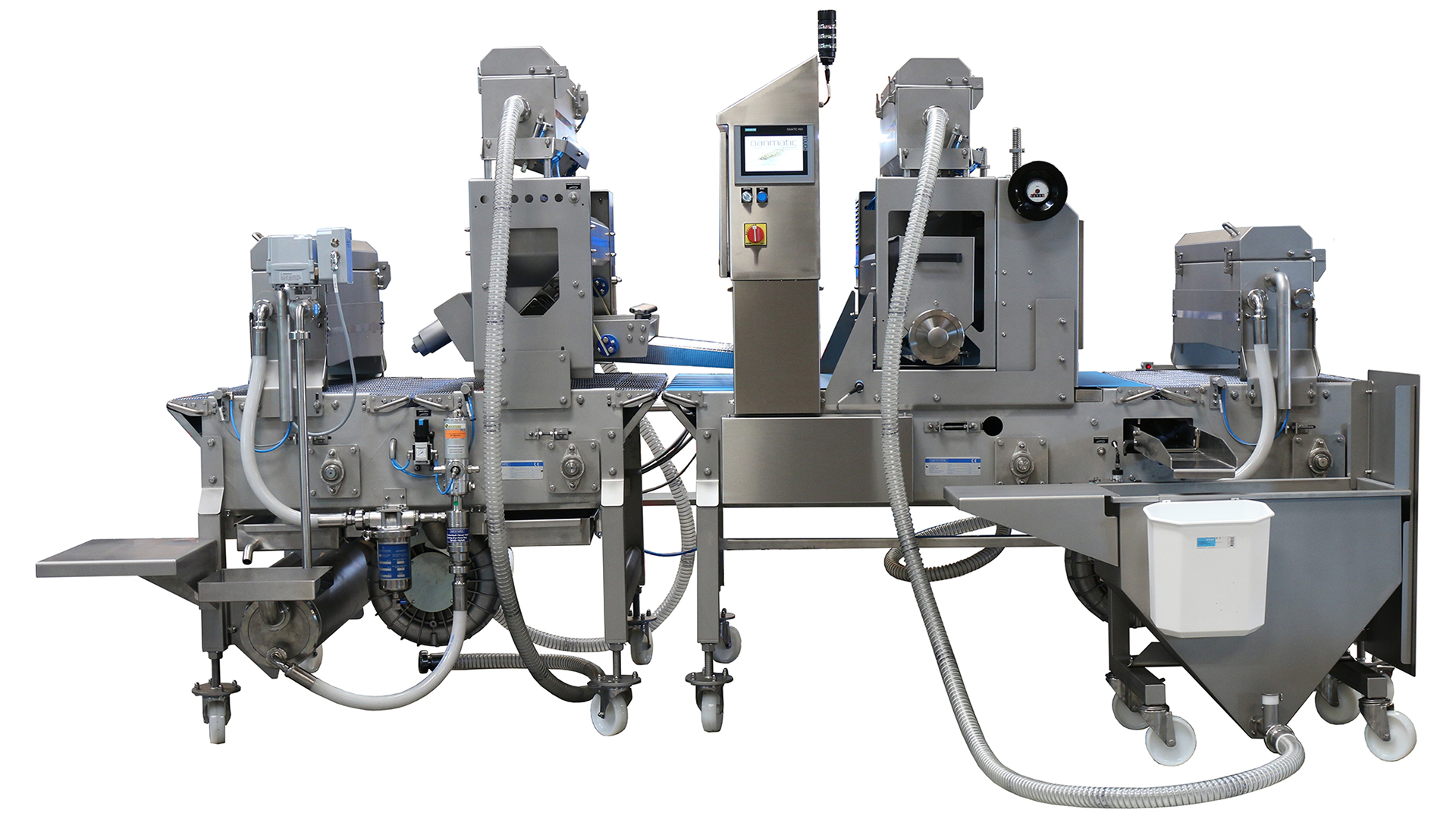

Danmatic’s Décor Unit is a modular system designed for easy and precise decoration of dough pieces.

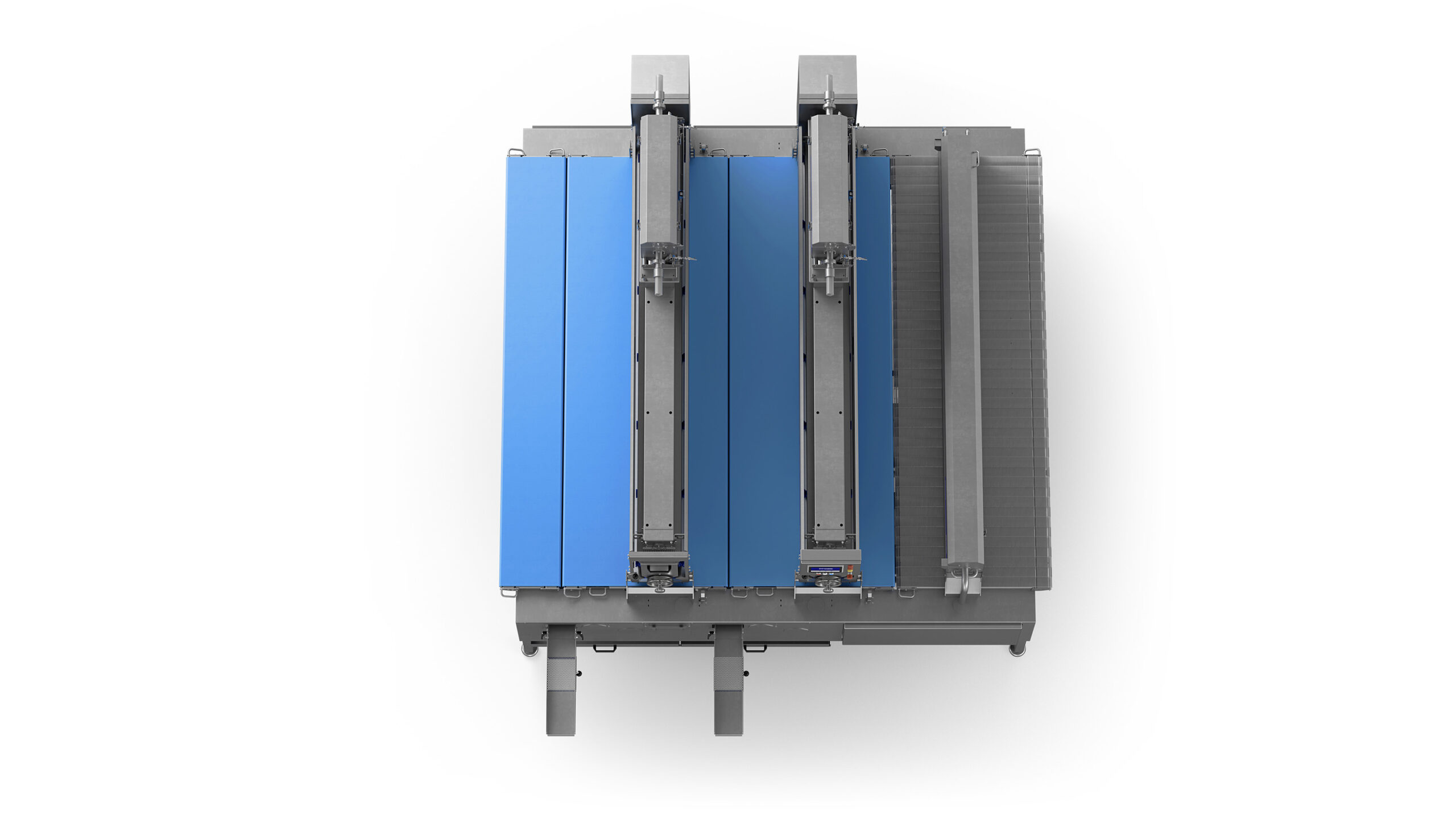

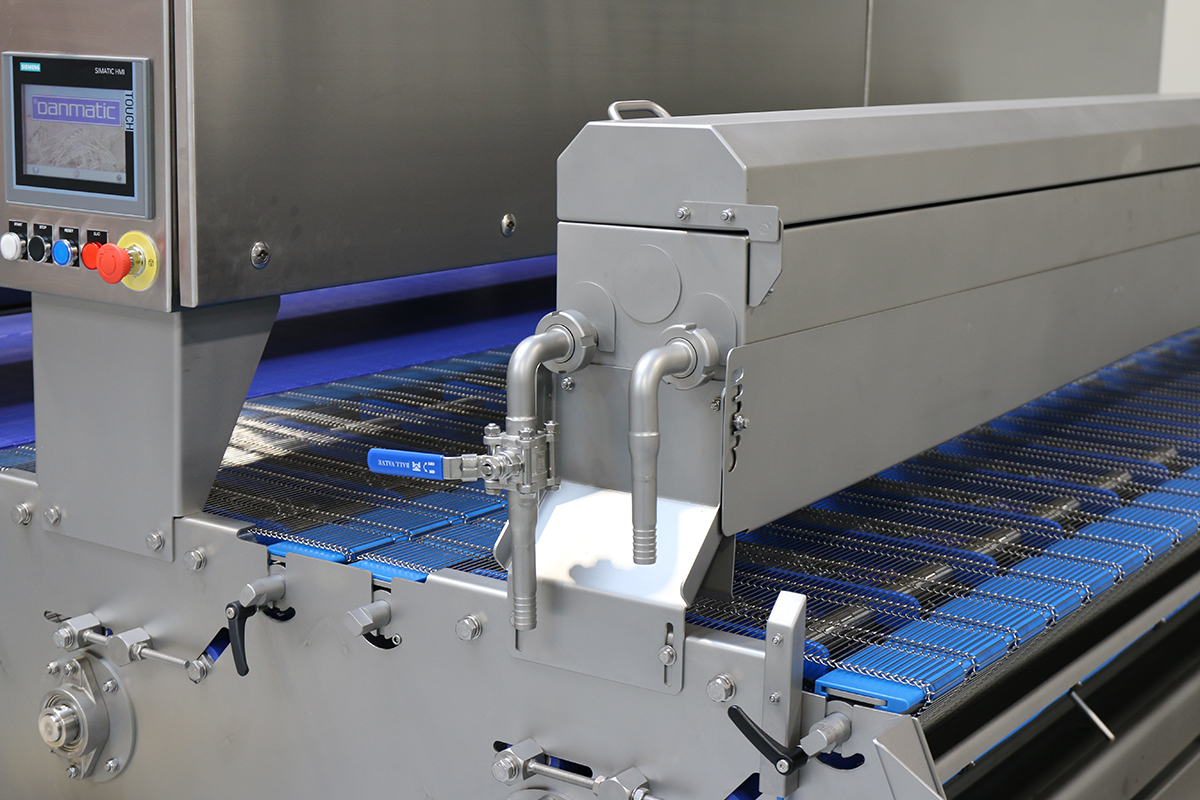

The Décor Unit features a coveyor belt with three sections, a spray unit system, a seeder and a vibrating conveyor.

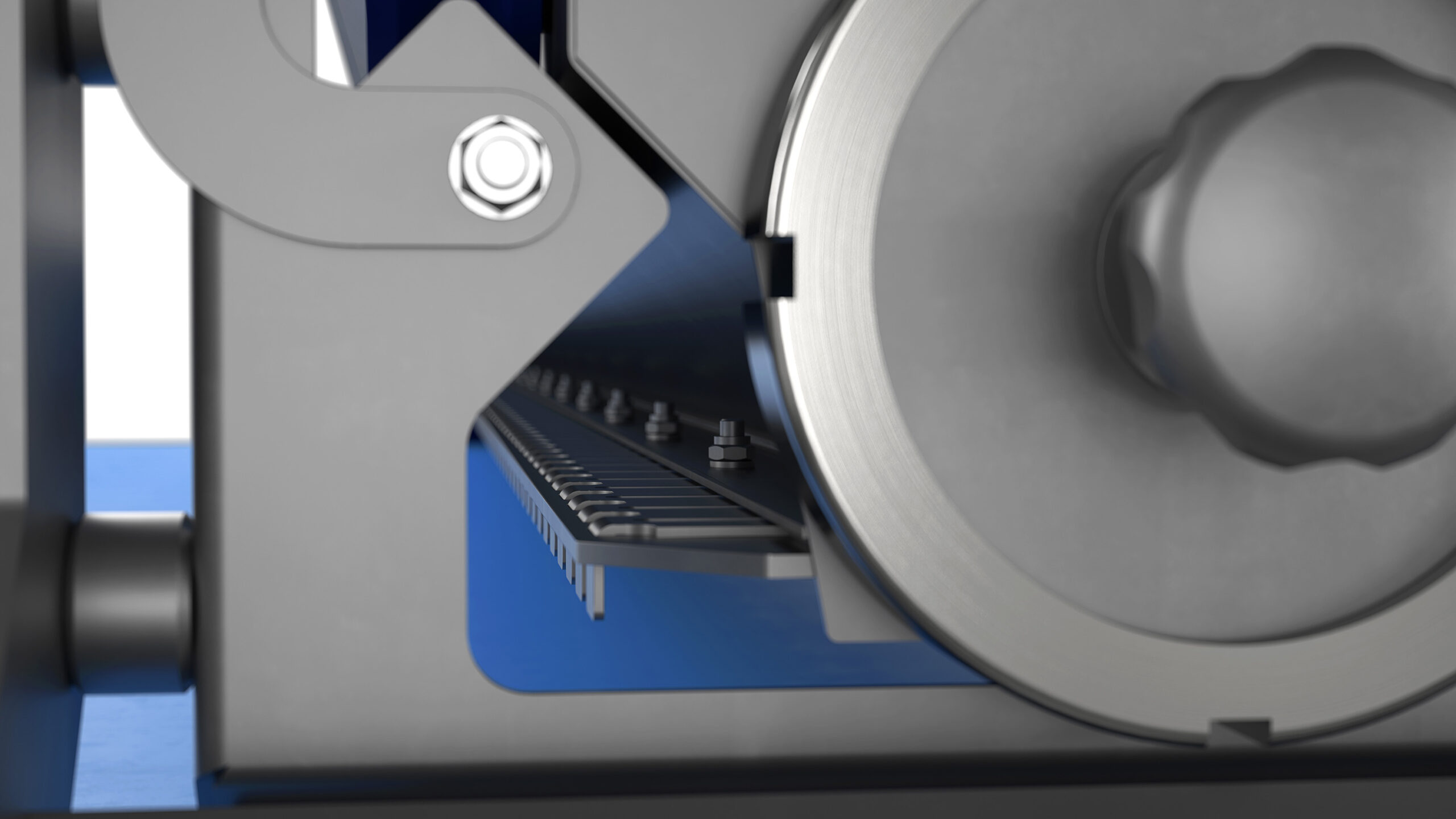

The spray system gives a nice and even application of liquid to the products and the seeder decorates the products precisely for a perfect result.

By having the conveyor belt split into separate sections, the liquid on the conveyor belts after the spray system is minimized. This makes it possible to reuse the excess decorations from the conveyor belt, as they fall into the vibrating conveyor mounted beneath the transition between the last two conveyor belts. In addition a dry conveyor belt helps to keep the unit clean and run longer production time between stops.

The vibrating conveyor transfers the surplus decorations sideways away from the line. The seeding hopper is a separate unit and can be easily replaced when changing decorations.

Technical data

- A Stand Alone Unit that is operated via touch panel

- Electric cabinet integrated in the unit

- Belt width from 700 up to 2,500 mm

- Length from 2,000 mm for Décor Unit with 1 seeding station

Options

- Multiple seeders

- Extra seeding hoppers

- Automatic refilling system for topping (Vacuum conveyor)

- Transfer trolley for extra seeding hopper

Download datasheet

Feel free to download the datasheet on our Danmatic machines and learn more about our innovative products.

Please contact us

Please call us or send your general inquiries.