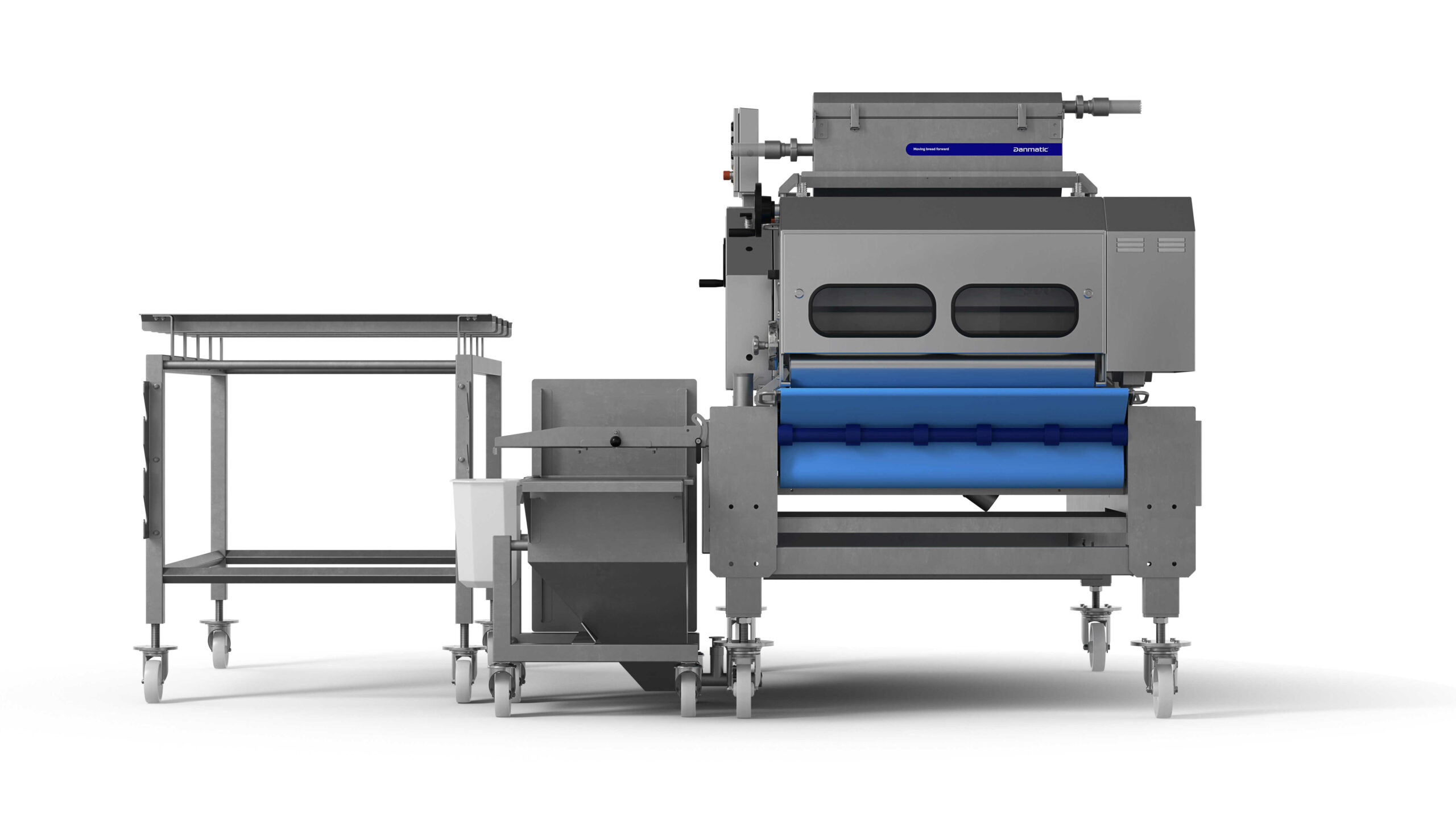

Décor Unit 700-1500 (Moistening Roller)

Danmatic’s Décor Unit is a modular system designed for decoration of freestanding buns, rolls, Kaiser rolls and full doughsheet products.

Danmatic’s Décor Unit is a modular system designed for decorating of free-standing bread. The Décor Unit features a two-piece conveyor, a moistening roller system, a seeder and a vibrating conveyor.

The moistening roller system ensures that the liquid is applied only to the products while the belt stays dry. This gives the possibility to reuse the surplus topping, as this falls into the vibrating conveyor mounted between the two belts.

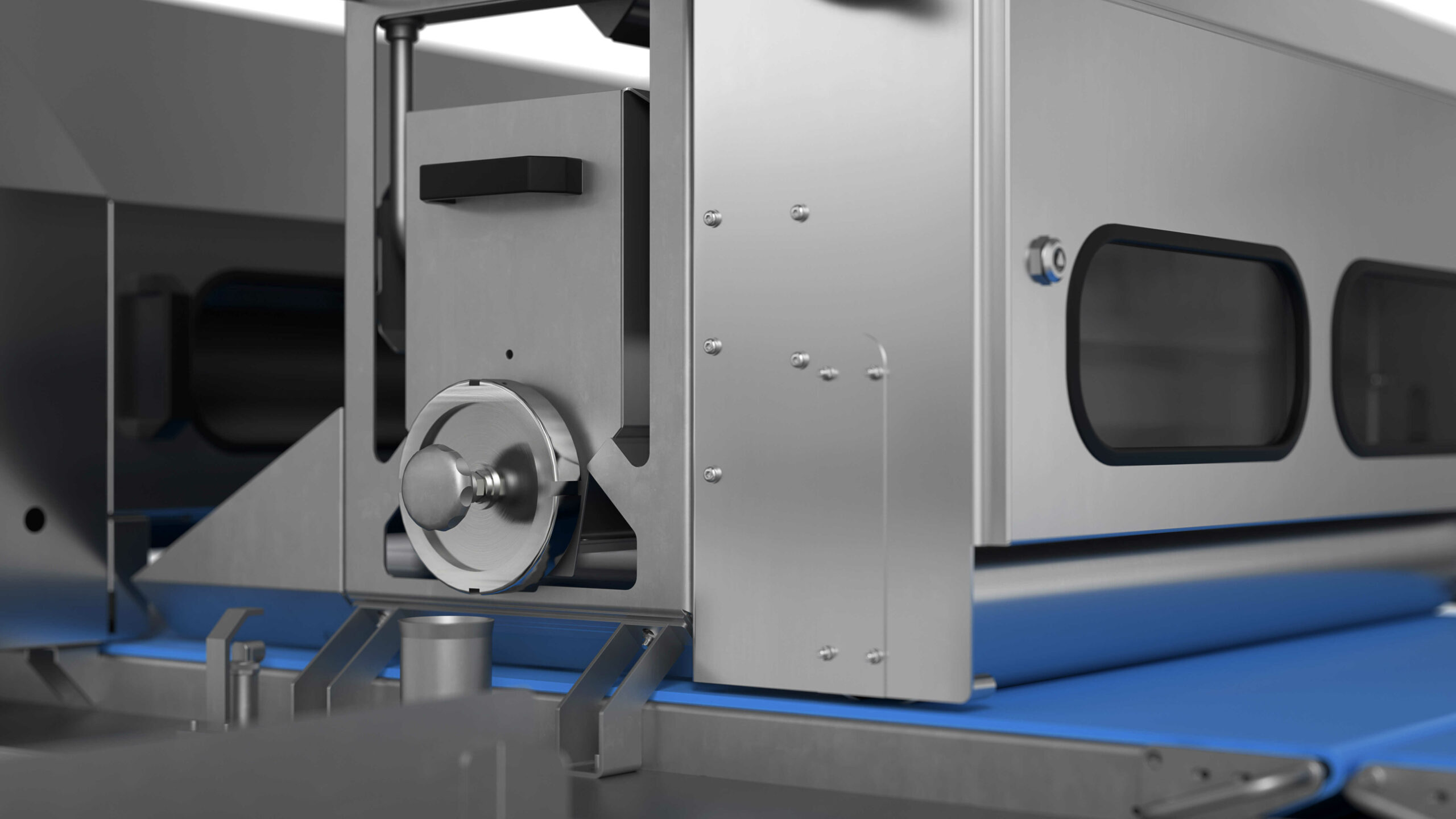

The vibrating conveyor transfers the surplus topping sideways away from the line. The seeding hopper is a separate unit and can be replaced when changing toppings. A flex coupling between the hopper and drive station ensures quick replacement of the hopper without using tools. Replacing the hopper takes less than a minute.

Technical data

- A Stand Alone Unit that is operated via touch panel

- Electrical cabinet build into the conveyor.

- Belt width: up to 1565 mm

- Max working width of Moistening roller up to 1.450 mm

- Length of Décor Unit with 1 seeding station: 2000 mm

Options

- Multiple seeders

- Extra seeding hoppers

- Automatic refilling system for topping (pneumatic vacuum conveyor)

- Pressing roller

- Mobile storage trolley for extra seeding hoppers

- Transfer trolley for seeding hopper

Download datasheet

Feel free to download the datasheet on our Danmatic machines and learn more about our innovative products.

Please contact us

Please call us or send your general inquiries.