Target Seeder and Target Spray unit

Danmatic’s Target seeder and Target Spray Unit with productdetection which reduce udsage of seeds with up to 47% and a ROI in less than 10 months.

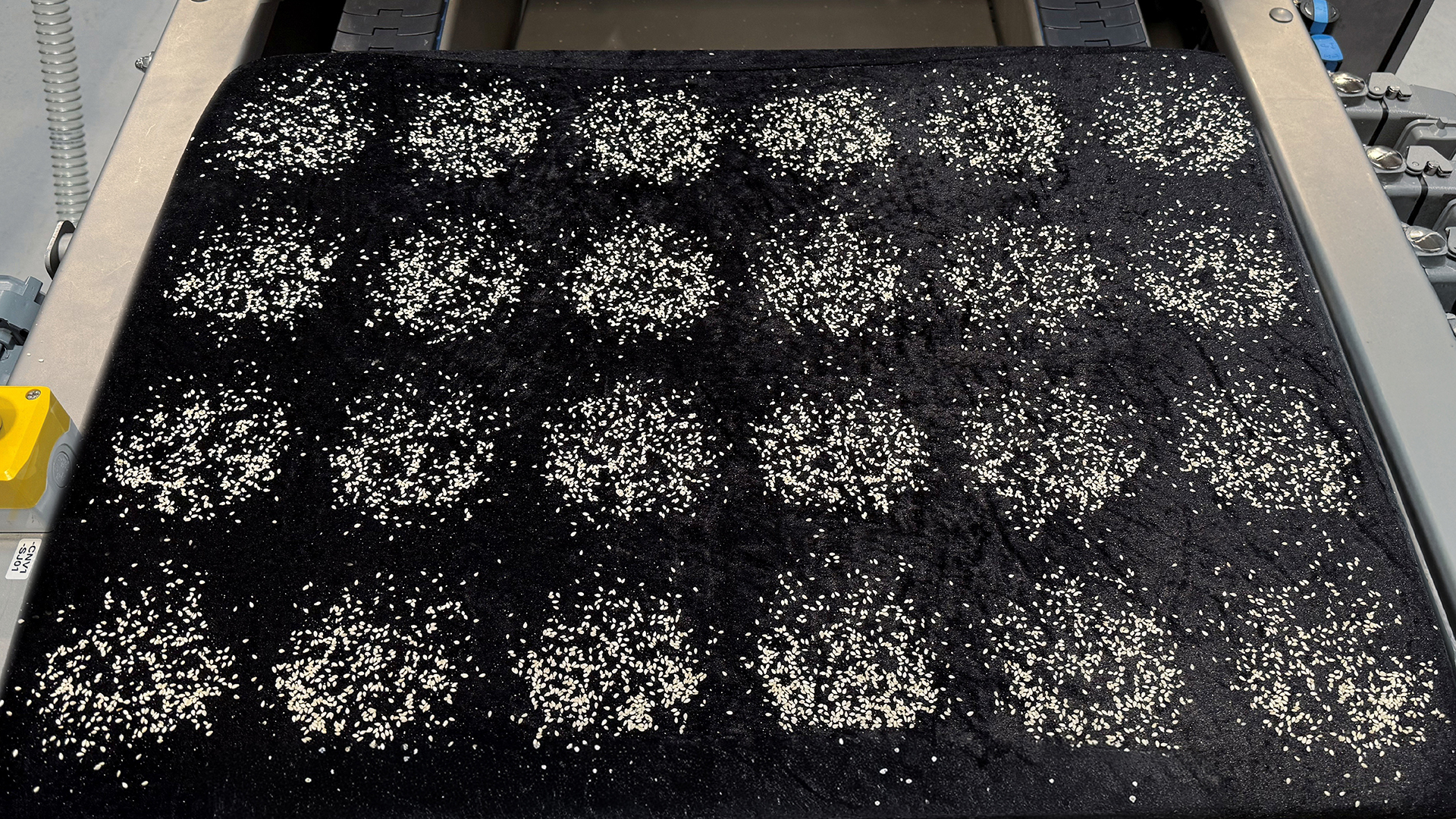

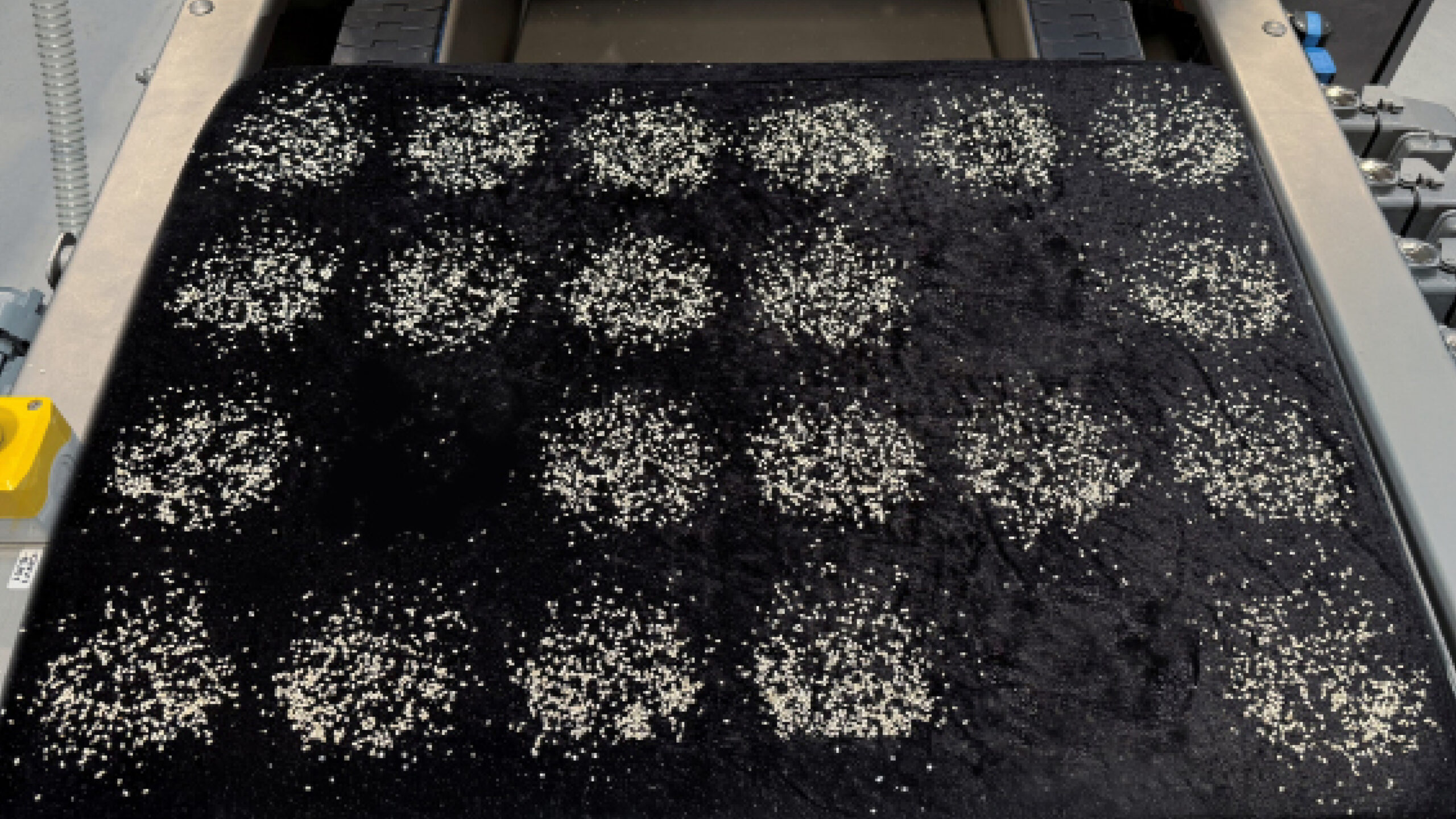

The Zero Waste Target Seeder and Target Spray Unit with productdetection is especially designed for reducing usage with up to 47% of seeds and costs for cleaning and re-coating of pans.

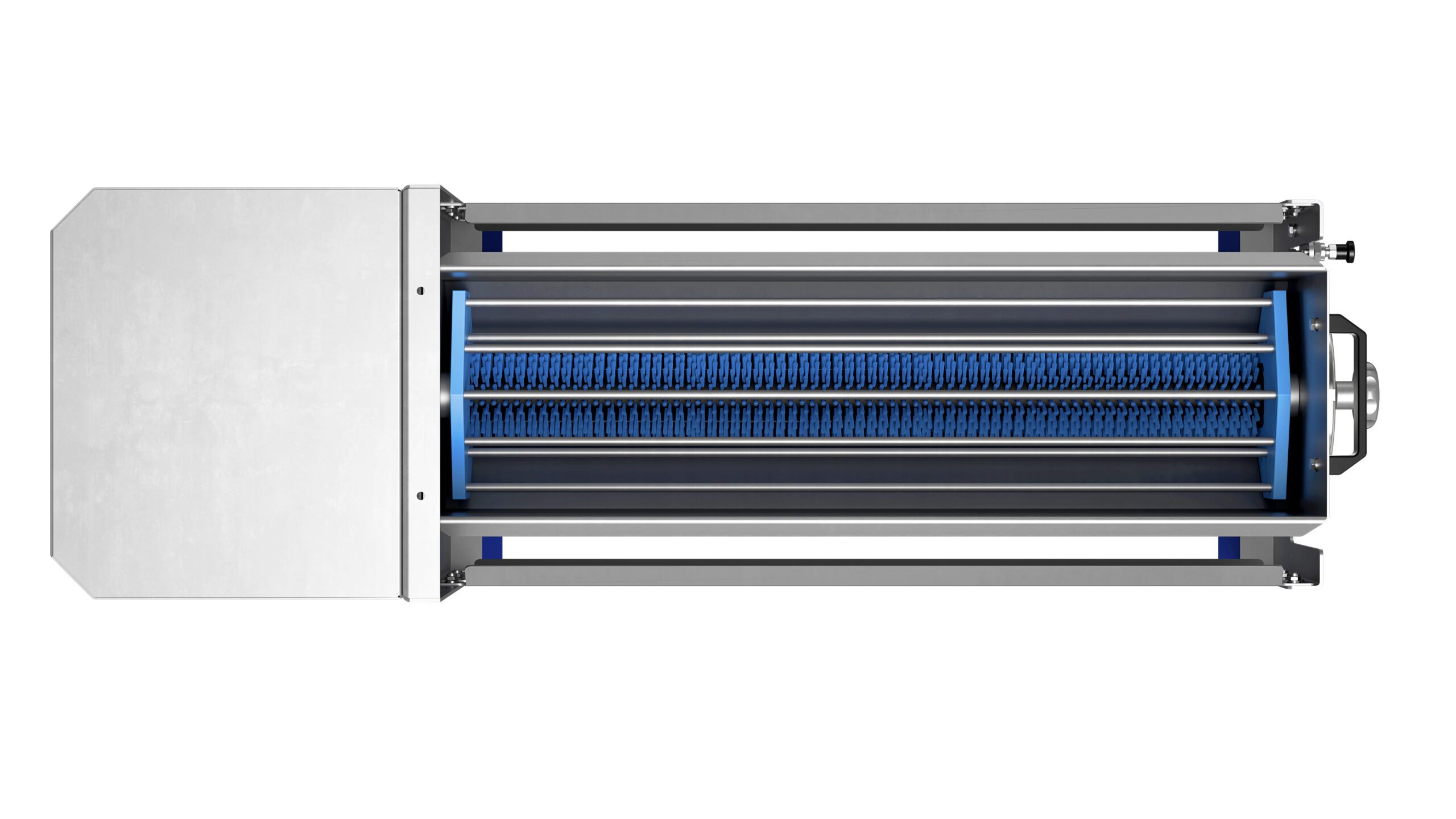

The new Danmatic Zero Waste Target Seeder and Target Spray Unit offers advanced precision by seeding not only in exact round positions, but now also in circular patterns. In addition, it features product detection technology, ensuring that seeds are placed only on the dough itself. This means no empty spaces in the tray or pan are seeded, significantly reducing waste and increasing efficiency.

There is not only a bottom-line benefit but also social responsibility as food manufacturers to ensure we are reducing waste in every way we can.

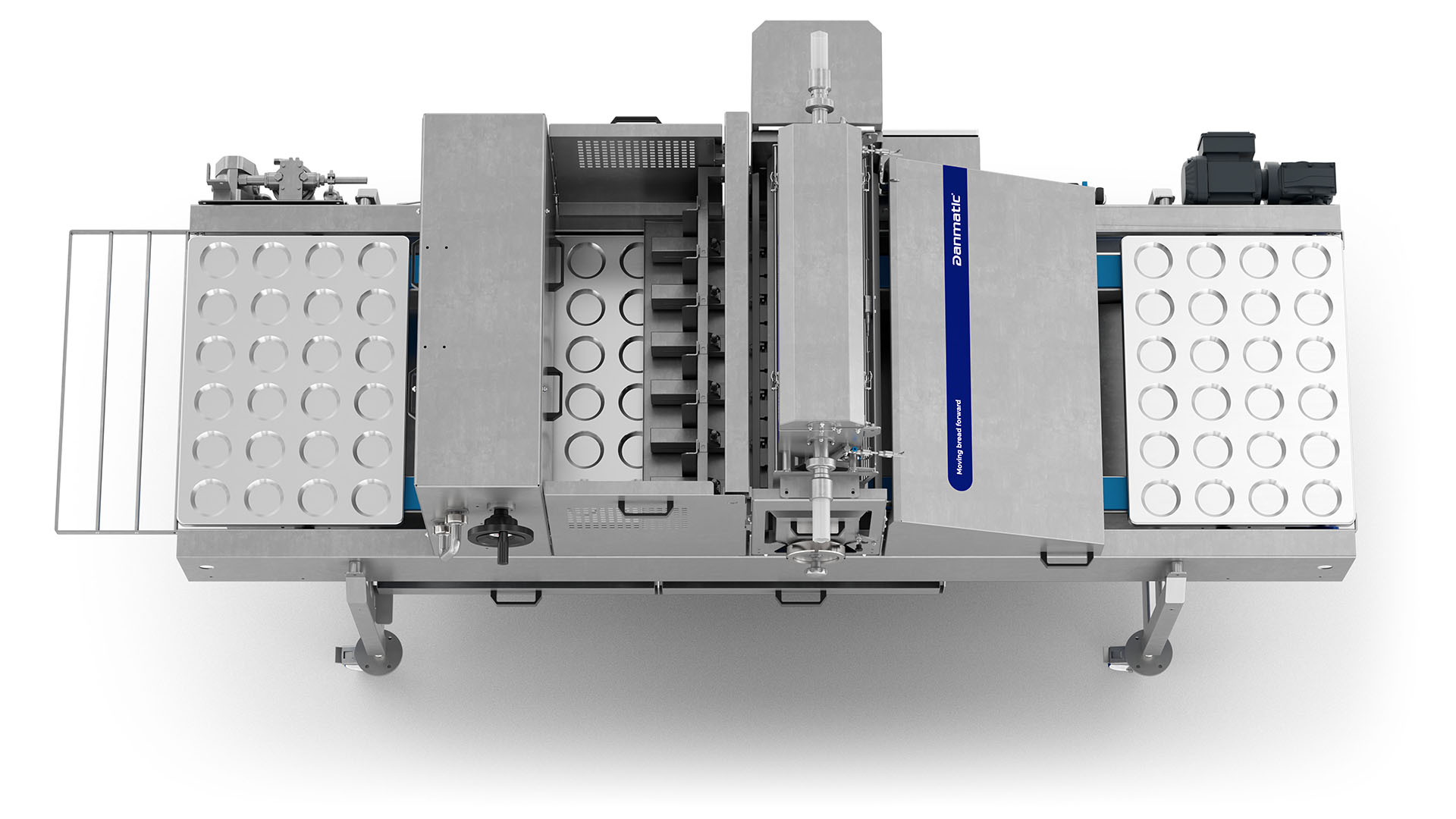

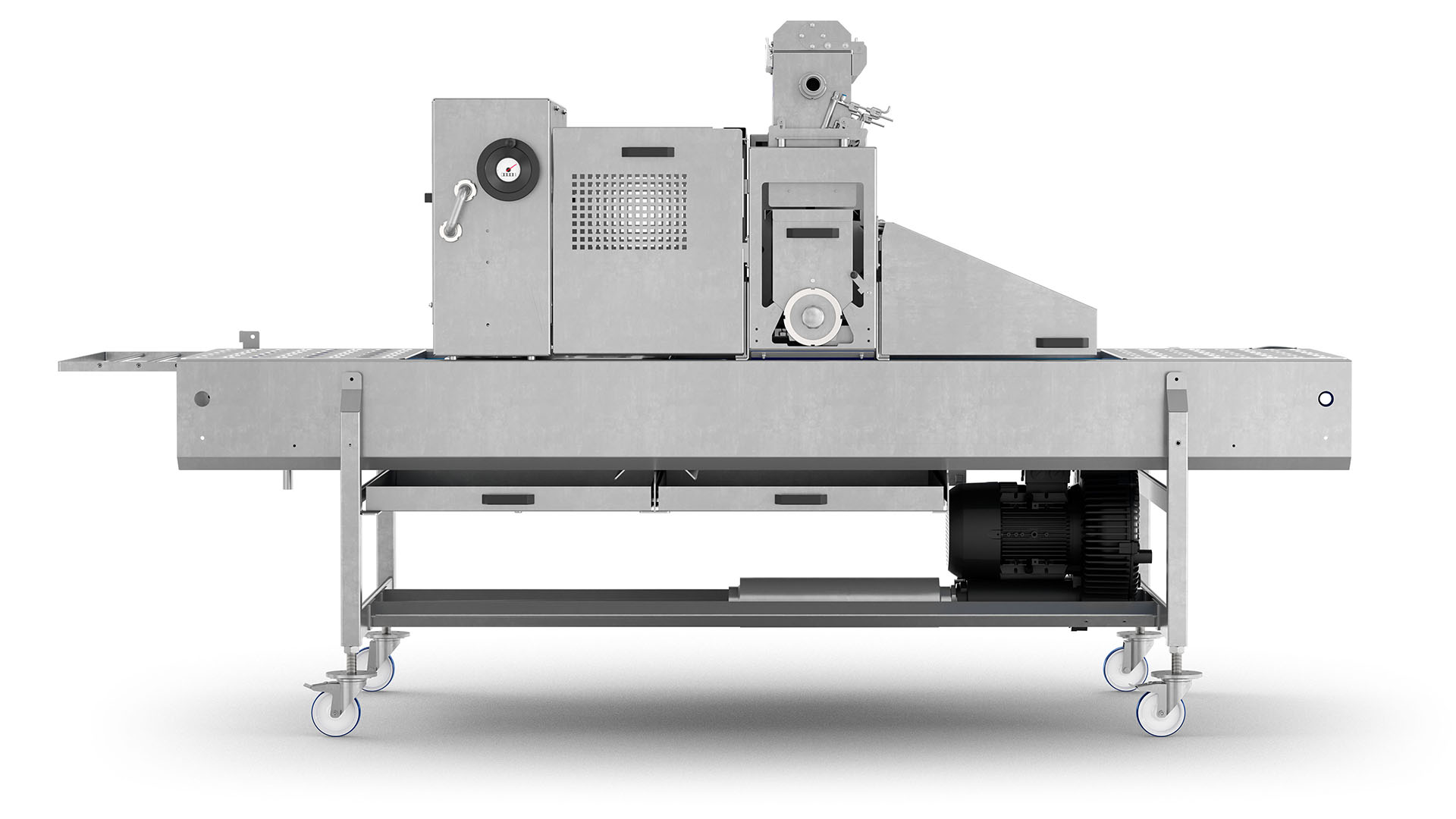

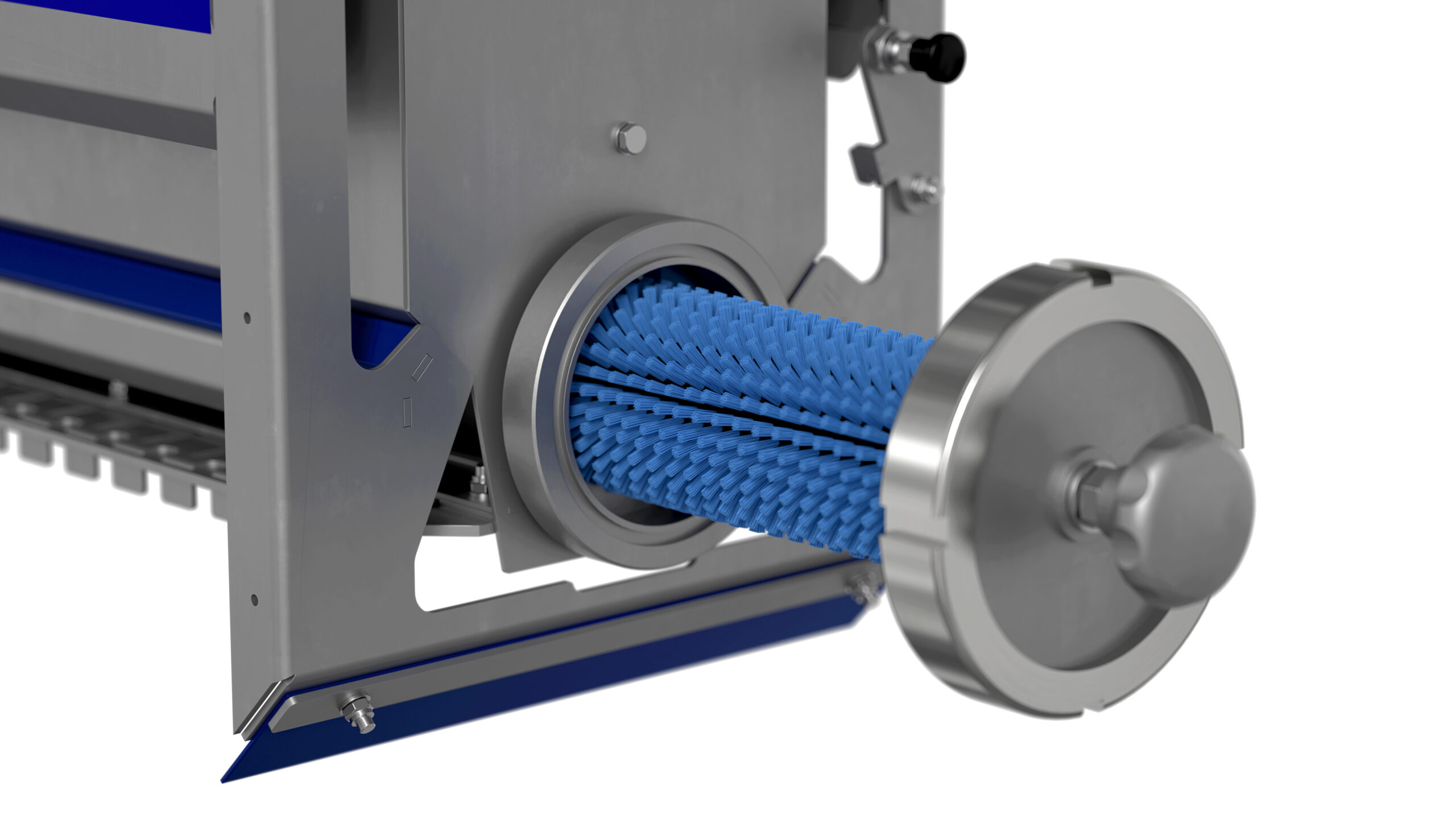

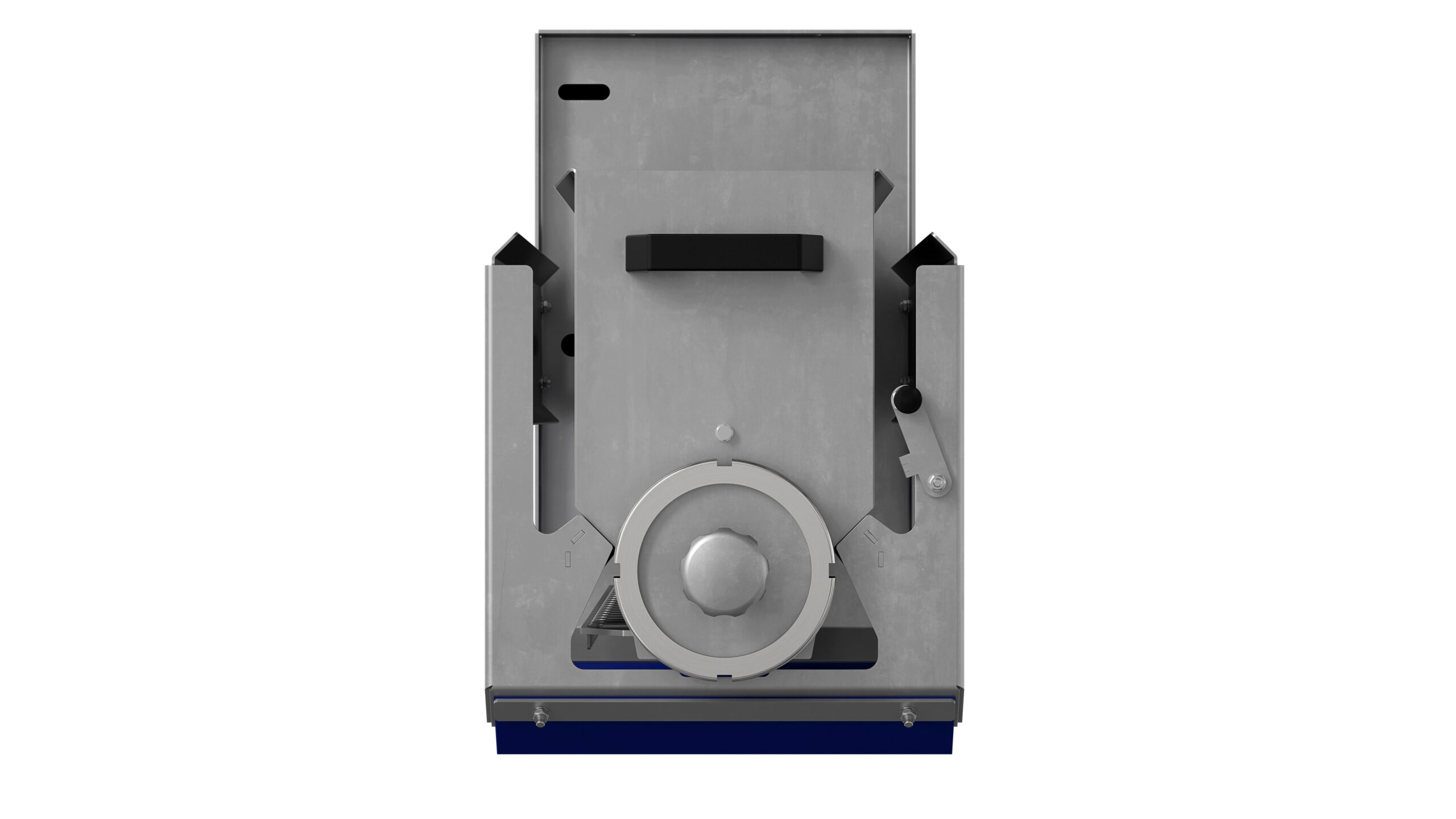

The seeding hopper is a separate unit and can easily be replaced when changing toppings. A flex-coupling on the backside will ensure a quick replacement of the hopper without the use of tools. Replacing the hopper takes less than a minute.

The optional vacuum conveyor automatically refills the seeding hopper.

Technical data

- Available in seeding width from 300 to 1300 mm

- Mobile unit operated via its own PLC-control

- Automatic productdetection - no product - no seed

- Manufactured in stainless steel and food approved materials

- The vacuum conveyor is ATEX approved

Options

- Extra seeding hoppers

- Different type of brush suitable for different type of topping

- Target manifold for extra precision

- When using toppings that may clog up, an agitator can be fitted in the hopper

- Height adjustable framework

- Mobile trolley for storage of extra seeding hoppers

Please contact us

Please call us or send your general inquiries.