Equipment overview

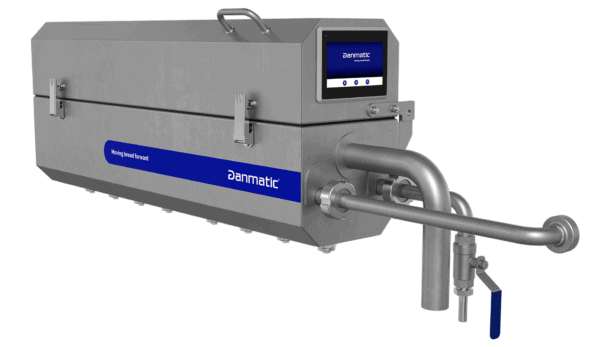

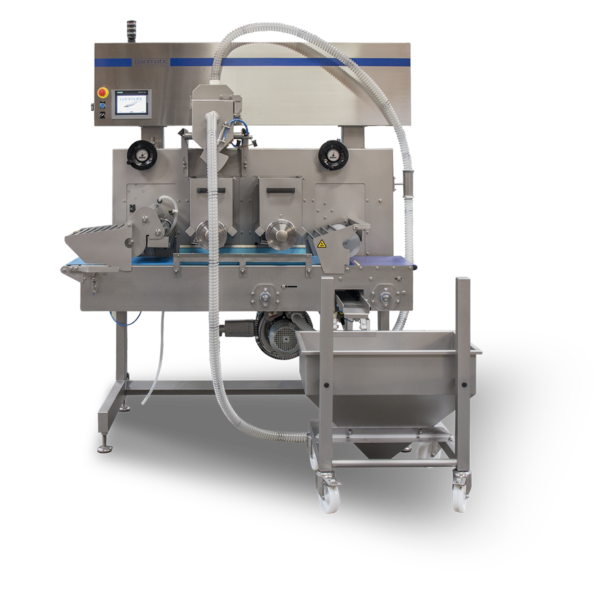

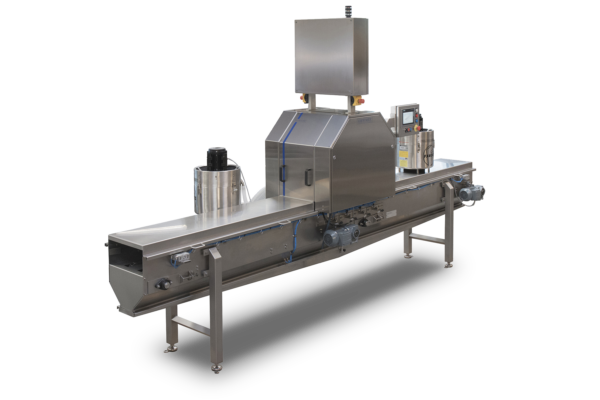

The perfect choice for:

- Precise spraying

- Minimal waste

- Easy to incorporate in

existing lines

The perfect choice for:

- Energy consumption is reduced with up to 50%.

- Topping costs is reduced with up to 30%

- The surplus topping are kept dry and can be reused.

The perfect choice for:

- Significant reduction in topping consumption

- Seeder with exchangeable hopper

- Seeding hopper with adjustable seeding width

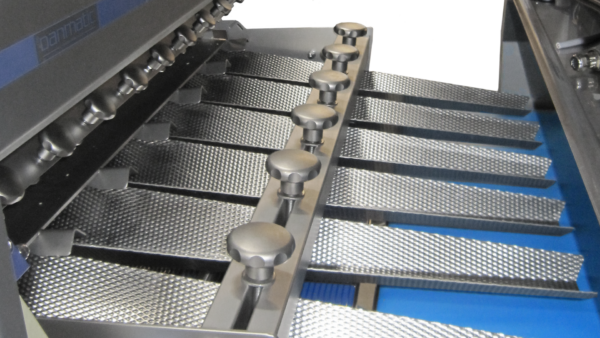

The perfect choice for:

- All types of toppings

- Constant flow of toppings

- Precise and minimal waste

The perfect choice for:

- Reuse of toppings

- Less waste of toppings

- Efficient and accurate

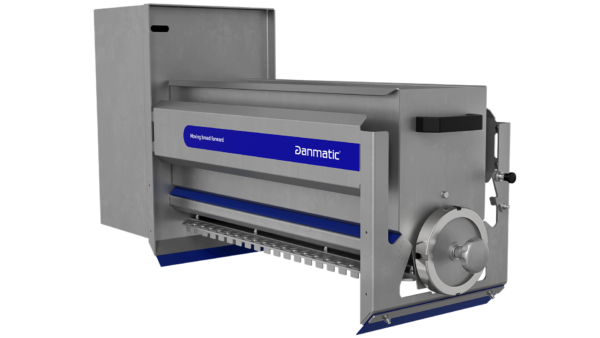

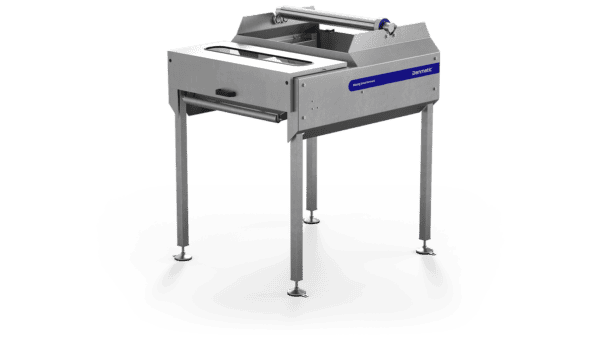

The perfect choice for:

- Smoothing the dough

- Improve product quality

- Uniformity across batches

The perfect choice for:

- Reuse of toppings

- Less waste of toppings

- Reduce expenses dramatically

The perfect choice for:

- Reuse of toppings

- Less waste of toppings

- Reduce expenses dramatically

The perfect choice for:

- Beautiful folded bread

- Adjustment of cutting depth and angle

The perfect choice for:

- Designed for precise cut's in dough pieces.

- Long lasting blades in stainless steel

- Easy cleaning

The perfect choice for:

- Eliminating cuts by hand

- Decorative patterns

- Visual appealing appearance

The perfect choice for:

- Eliminating cuts by hand

- Decorative patterns

- Visual appealing appearance

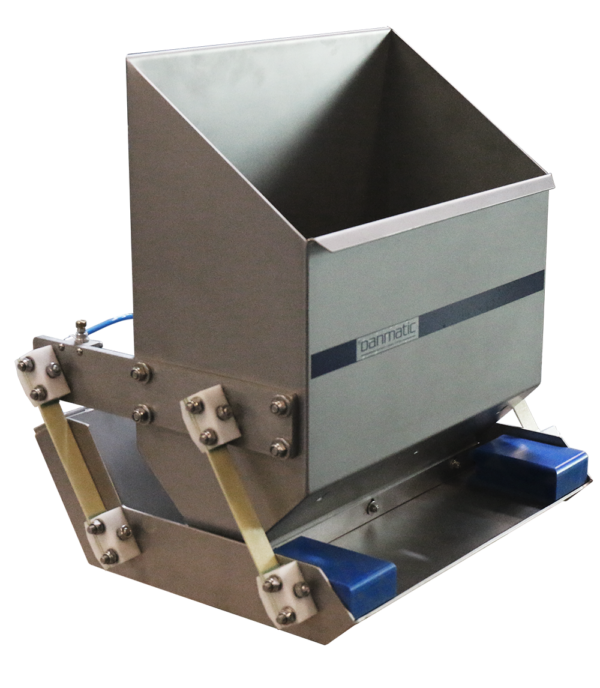

The perfect choice for:

- Significant reduction in topping consumption

- Seeder with exchangeable hopper

- Seeding hopper with adjustable seeding width

The perfect choice for:

- Significant reduction in topping consumption

- Seeder with exchangeable hopper

- Seeding hopper with adjustable seeding width

The perfect choice for:

- Significant reduction in topping consumption

- Seeder with exchangeable hopper

- Seeding hopper with adjustable seeding width

The perfect choice for:

- Significant reduction in topping consumption

- Seeder with exchangeable hopper

- Easy to incorporate in existing lines

The perfect choice for:

- Fast mixing of new batches

- Easy to drain and clean

- Safe storage and tidy workplace

The perfect choice for:

- Fast handling of trays

- Effecient handling of trays

- Employee saving

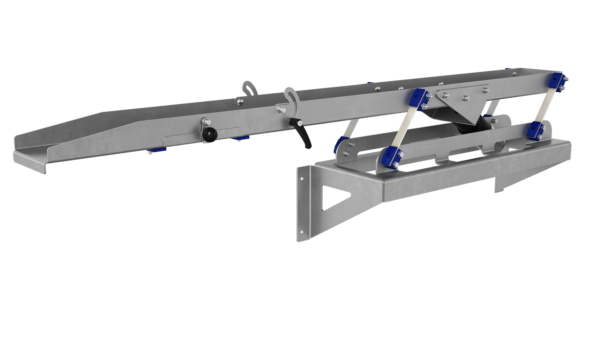

The perfect choice for:

- Ergonomic handling of trays

- Easy access to the tray trolley

- Steady flow of trays

The perfect choice for:

- Fast and easy change

- Labor saving

- Easy installation

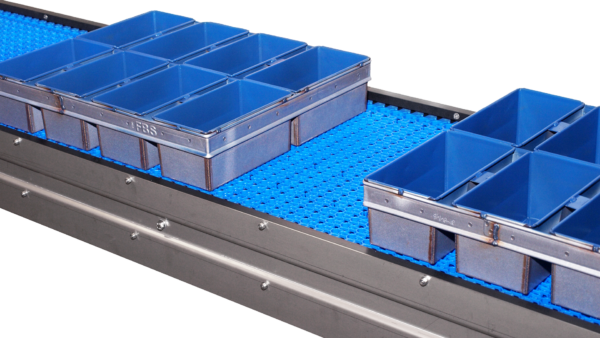

The perfect choice for:

- Efficient transport of trays

- Continuously running

- Gentle handling of trays

The perfect choice for:

- Fast and precise tray handling

- Efficiency - employee saving

- Ergonomic working conditions for personell.

The perfect choice for:

- Fast and precise tray handling

- Efficiency - employee saving

- Ergonomic working conditions for personell.

The perfect choice for:

- Fast and precise tray handling

- Efficiency - employee saving

- Ergonomic working conditions for personell.

The perfect choice for:

- Fast and precise tray handling

- Efficiency - employee saving

- Ergonomic working conditions for personell.

The perfect choice for:

- Easy and time saving

- Automatically locked in the correct position

- Gently handling of the dough

The perfect choice for:

- To ensure clean and healthy environment

- Efficiency - employee saving

- Adjustable side guides for straps.

The perfect choice for:

- Grouping of bread

- Efficient transportation

- Optimal for trayhandling

Tray Handling System

/

Depanner

Tray Handling System

/

Depanner

The perfect choice for:

- Automatic Handling of Trays

- From oven output

- Distribution to multiple lines

The perfect choice for:

- Vacuum picker of baguettes or/and bread

- Infeed to drilling maschine

- Small and large bread handling

The perfect choice for:

- Correct handling of baguette for French Hotdog

- Long operational life and stability due to robust steel design

- Capacities from 3.000 up to 24.000 pcs/h.

The perfect choice for:

- Efficient and ergonomic handling of drilled baguettes

- Labor saving

- Increasing productivity

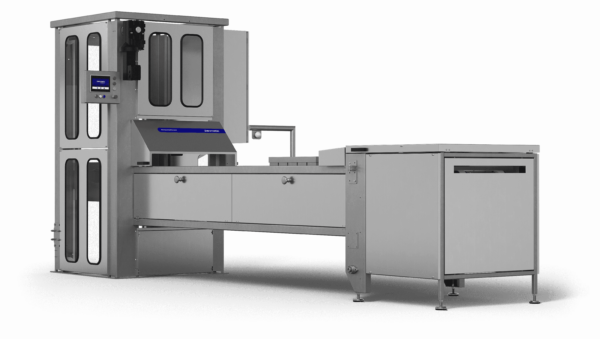

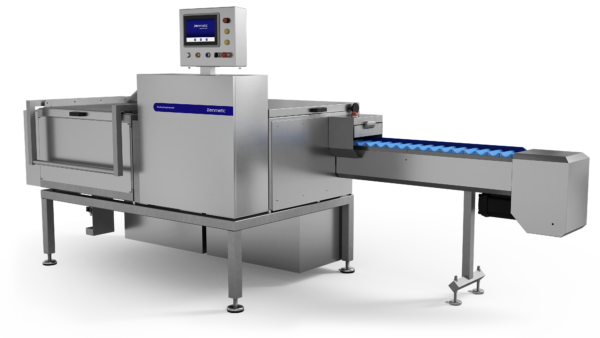

The perfect choice for:

- Integrated control unit

- Operated with its own PLC-control

- Stainless steel and food approved materials

The perfect choice for:

- Operated with its own PLC-control

- Stainless steel and food approved materials

- Customer adapted solutions are avaliable

The perfect choice for:

- Easy slip from oven belt

- Continuously uniform coating of the oven belt

- Improves the lifespan of the oven belt

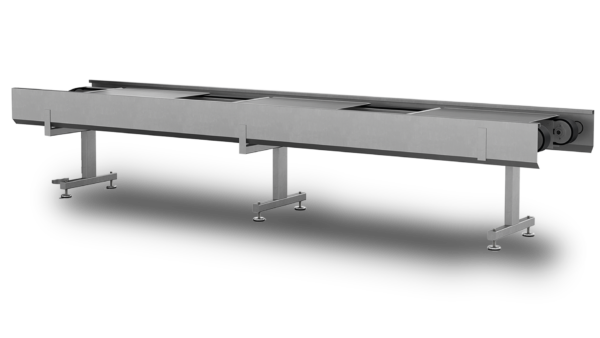

Special Standard Equipment

/

Conveyor

Special Standard Equipment

/

Conveyor

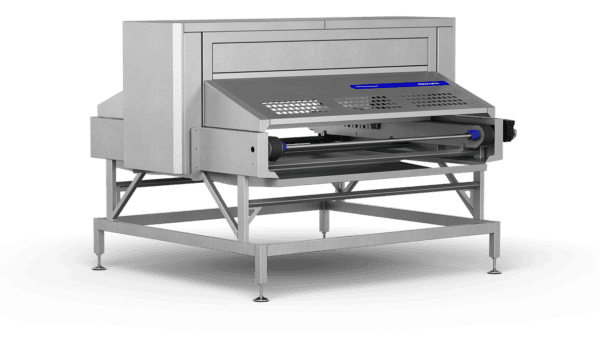

The perfect choice for:

- High performance

- Integrable into existing lines

- Low maintenance

The perfect choice for:

- High performance

- Little space required

- Low maintenance

The perfect choice for:

- Automatic depositing dough into straps

- Precise oiling and seeding

- Handling up to 600 straps pr. hour

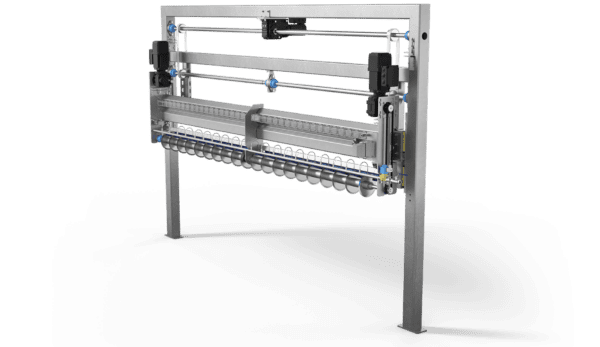

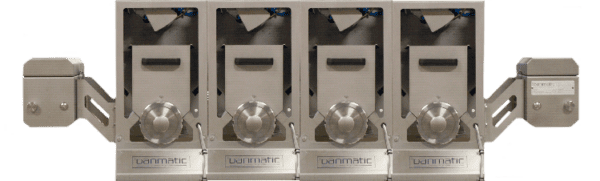

The perfect choice for:

- Significant reduction in topping consumption

- 4 x Seeder Unit

- Seeding hopper with adjustable seeding width

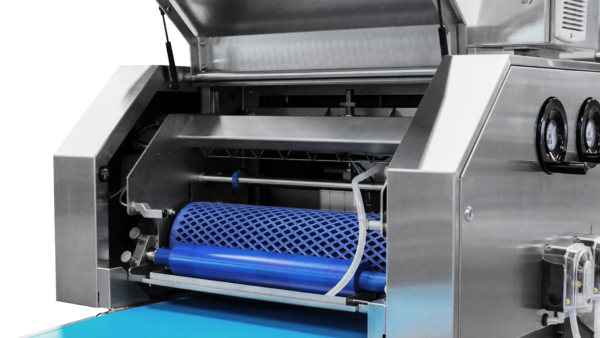

The perfect choice for:

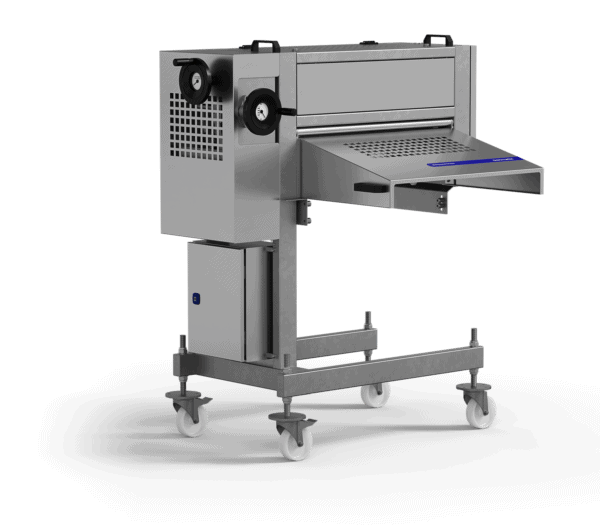

- Usable for, water, starch, combinations, oil, egg wash and more

- Easy height adjustment of the rollers by a handwheel with scale

- Integrated hose pump